Rangi Reeves has recently joined AI&S as our new Quality Assurance Manager. Rangi’s role is a very pivotal role within the organisation, not only for the business, but also to our clients. Rangi not only holds the position of QA Manager but also is a qualified welding supervisor (AS2214). One of Rangi’s key responsibilities is to check all inwards goods coming from our suppliers. This not only includes laser cutting and painting components, but also basic items like the material supplied, nuts and bolts and consumables. It is critical to ensure these items are correct to the drawings, quantities required and the right thickness and type of material ordered. This constant checking ensures our clients receive on time delivery and a quality product delivered.

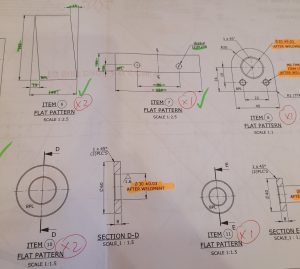

The QA manager’s role is varied and diversified having to check not only inward goods but also fabricated and machined components that we make for customers. It is critical to ensure the dimensions are correct to the drawing and it looks the same as what the customer requires. AI&S has a four step QA process that means each part being manufactured goes through a system of “stop gate checks” before the end product is produced. Things the QA manager is looking for are, the final product quality and workmanship, the overall finished product is of a high standard and the dimensions are exactly made to the client’s requirements. Each part is measured against the set of workshop drawings given with each job.

In nearly all circumstances, all the parts we manufacture for customers requires specialized specifications that have to adhered and made to such as, AS/NZS 1554.1 In general this is a standard that 90% of jobs in any workshop are made to: the way the parts are welded, the size of the welds and also the finish of the product.

Many of our clients now require Manufacturers Data Reports (MDR’s) on all jobs which comprises of AI&S supplying a detailed report on materials used (Test Certs), weld specifications (weld procedures and fabricator qualification), paint specifications that come from our supplier, and the dimensional drawings of the component being made.

As a Welding Supervisor, it is our QA manager’s responsibility to make sure that each fabricator is qualified and capable of doing the work to a high standard. Each fabricator goes through a series of weld tests on a regular bases to ensure their skills are of high class and quality, again something our QA manger schedules and is responsible for. This rigorous testing ensures the welds themselves are to standard specified by the customer.

“As a QA Manager there are several common mistakes or issues that I see from customers, which in most cases the client is unaware of, when getting a product manufactured.” Rangi said. “These are, lack of information on drawings, i.e., the weld size, sometimes the welds are either too big for the material being used or to small, not enough detailed dimensions on the drawing, which is very common, and generally, not enough drawings to complete the job. We often have to go back to the customer and get more information so we can complete the job.”

Are you looking to work with a company that focuses on high quality goods being delivered on time, then why not give AI&S a call today, 07 33761277.

AI&S – Tailored Engineering When Quality Counts