Sometimes it’s what happens in the background that is the most important part.

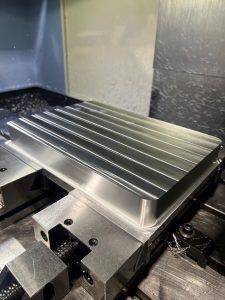

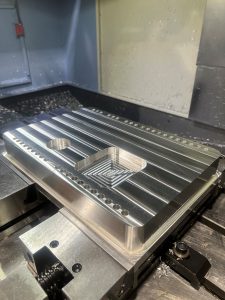

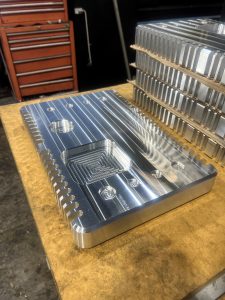

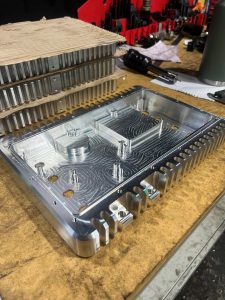

Material 6061 – T6 Aluminium

This was a complex par t with multiple operations, corner radii on the bottom of the pockets, small tapped holes, deep pockets with massive amounts of material removal and heatsink fins surrounding the outside. There were several challenges in machining this part. The most important part was planning it out and formulating the order of operations. Understanding how we were going to hold this part, especially on the last operation after removing 21% of the original billet and the wall thickness getting down to 3mm. The tooling used on this particular project were all aluminium specific, sharp, positive rake and long series’ cutters. We had to modify/grind/relieve a few endmills to get right into and finish the deep pockets.

However, the programming of this job was definitely the trickiest part.

Do you want experienced programmers to program your next critical machining job, then why not give AI&S a call and see how we can help you.

AI&S – Tailored Engineering When Quality Counts